Glow Research

Research and Production Plasma Cleaning Systems

Our systems report the RF power actually going into the chamber in 1 watt increments.

Glow Research System are used in Production as well as R&D, University; applications

Organic removal, photoresist removal, decap, bonding (PDMS), and FA applications.

High purity quartz chambers or anodized aluminum chambers are available.

At Glow Research we are extremely proud that our systems have

Contributed to advancements in the Scientific community, MEMS,

Biomedical and the Semiconductor industry

Glow Plasma Systems

The GLOW plasma system is designed for high reliability and process flexibility. No tuning is required! The GLOW is suitable for lab, university or production applications. It can perform a host of applications such as plasma cleaning, removing photoresist, prebond cleaning/conditioning, PDMS bonding and organic removal. Has three electrode shelves—(1) low intensity plasma, (2) grounded plasma or(3) RIE type plasma processing--providing a great deal of process flexibility. IN STOCK. TRIAL SYSTEMS AVAILABLE

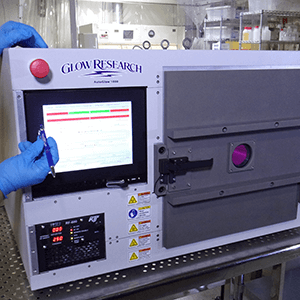

AutoGlow 1000

AutoGlow 1000 is a large chamber production plasma system with multiple shelves for direct plasma, downstream plasma or RIE processing. Each sample shelf is 13.75” (35mm) x 16.75” (42.8 cm deep). Up to four MFC’s. The AutoGlow 1000 is controlled by our advanced touch screen control system. Made for your 24/7 production needs. Can process 300mm wafers or large batch sizes. Under 8% uniformity for etching, plasma descum or photoresist removal. Great for plasma treatment or prior to bonding.

AutoGlow Plasma Systems

AutoGlow 200 is designed for 8” (200mm) substrates or larger samples with RIE and plasma capability. 300 or 600 watt, 13.56 MHz system with adjustable power in one watt increments. Anodized aluminum chamber. Can be used for etching, FA applications, cleaning prior to die bond, organic removal, PDMS bonding or plasma cleaning. Our AutoGlow 300LF (low frequency) system sells for as low as $19,000. Two shelves (one powered, one ground) and sized 8.375” x 15” (220 mm x 381 mm). The quartz chamber AutoGlow can process 25 4” (100mm) wafers per run, or up to a 6” wafer.

Software Upgrades on Older Plasma Systems

Glow Research makes the entire system (RF generator, RF matching, control system, chamber and gas flow modules). Our systems are used in 3 shift/day production as well university/R&D applications. We can install our Genesis Software Control System on older plasma systems—brings new life to older systems.

See a video of our Genesis Software and FIND OUT MORE.