Glow Research provides different types of OptiGlow plasma systems

- OptiGlow ACE: For Ashing/Activation, Cleaning, Etching (ACE). Anodized aluminum chamber, 10 to 150 watts, automatic tuning 13.56 MHz, two flowmeters, Plasma or RIE style processing with oxygen, argon or CF4 chemistry. Ideal for etching IC packages or other etching/cleaning applicaitons. Has sample holder with two shelves…top shelf for RIE, bottom shelf for plasma processing. Designed for a long processing time–push button, automatic operation.

The OptiGlow ACE can be used to remove residual plastic from IC’s for Failure Analysis. Please see our Plasma Applications page for more technical details. The following data comes from our Customer, JHT Instruments

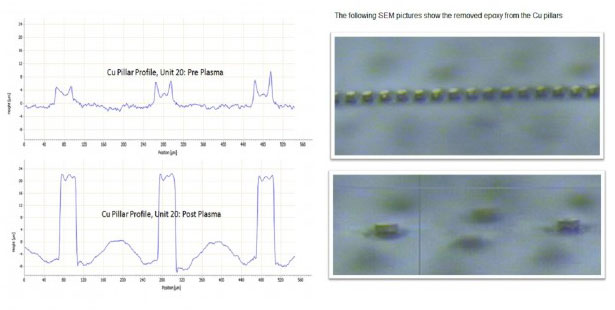

Removing TCNCP Encapsulant Material to reveal Copper Pillars with the OptiGlow ACE plasma system (see Plasma Applications for more data)

The following data and graph shows before and after results for removing Encapsulant material from Cu Pillars:

Increased surface energy of a material improves its adhesion characteristics, thereby allowing improved bonding, gluing, markability, paintability, and coatability.

- Hydrophilic surface treatment

- Increase adhesion and capillary effects

- Hydrophilic treatment of micro channels

- Used in Bio MEMS and MicroFluidics

- Control of surface properties

- Improves electroosmotic flow(EOF) of various material

- Treatment of PDMS

- Impart protein and cell-repelling characteristics for some materials

- Ideal for use prior to coating, laminating or deposition processes

- Cleans, activates prior to printing or bonding

Hydrophobic: Contact lens material without OptiGlow plasma treatment.

Hydrophilic: Improved webabilty with OptiGlow plasma treatment.

Gas plasma treatment provides a fast, efficient method for surface modification of contact lens or various polymers and materials. OptiGlow plasma processing can increase wetability, improves lubricity, and enables deposition of bio-compatible materials. Contact lens plasma treatment is a common application where the lens surface is plasma treated to create a hydrophilic lens surface that is resistant to protein deposition. The plasma process allows for improved comfort and longer wear. Please see technical note under “Plasma Applications”.

OptiGlow Chambers

The plasma chamber, constructed of high grade 6061-T aluminum, is anodized and resistant to chemicals and easy to clean. Power is supplied to the RF and ground electrodes via feed-through rails. This allows for shelves for RIE or plasma processing.

The plasma chamber, constructed of high grade 6061-T aluminum, is anodized and resistant to chemicals and easy to clean. Power is supplied to the RF and ground electrodes via feed-through rails. This allows for shelves for RIE or plasma processing.

The OptiGlow ACE system’s control module monitors chamber pressure, pre-set power and actual power. For any plasma process, it is important to know the chamber pressure to ensure a proper and repeatable process. A relative chamber pressure is displayed on the front of the system.

Safety

All Glow Research systems have standard features include a button that terminates RF power and gas flow.Safety interlocks prevent activation of the RF power and gas flow when the chamber door is open or if covers are removed. All Glow Research plasma systems have passed rigorous testing and is CE Marked. Designed for US or International power (110 or 230 VAC).

For a complete demonstration of the ACE OptiGlow, Contact Us Today!