Rebuilt MARCH PX-1000 with Glow Research Software Control Under $45K. Click HERE for information on our AutoGlow 1000.

• Rebuilt by Glow Research, and in great working condition—12 month warranty

NOTE: We replace all of the old boards and upgrade with our own Software Control System–this allows us to fully support this great system with parts and upgrades. We add a throttle valve so you can control process gas flow independently from chamber pressure–very easy to set up in the software control.

• 600 watt solid state 13.56 MHz RF generator

• Internal RF matching network (rebuilt and modified for performance)

• Automatic tuning

• Stainless steel chamber (helium leak checked)

• Flexible shelf architecture allows processing of a wide variety of parts in either direct or downstream plasma mode

• Emergency shut-off button, located on the front panel, immediately terminates the gas flow and RF power. Safety interlocks prevent activation of RF power when the chamber door is open. Safety interlock has been added to the chamber door

• Two Mass Flow Controllers (Porter)–rebuilt and calibrated by our partner Precision Flow Devices https://precisionflowlab.com/

• Vacuum pump can be quoted and supplied (40-50 cfm with Fomblin oil recommended)

• Glow Research has taken over the support and parts for the Nordson March Plasmod, March Super Plasmod, PM600, Jupiter II and Jupiter III RIE systems.

• The PX-1000 platform designed to be set on a table, requiring minimal floor space. Full front access allows for convenient access to all interior components.

• The plasma chamber is constructed of 11-gauge stainless steel with aluminum fixtures for superior durability. The chamber has multiple removable and adjustable shelves to accommodate a range of part carriers, including magazines, trays and wafer boats.

• The PX-1000 Plasma System with shelves combines the reliability and process quality of the PX-1000 system with the proven benefits a unique shelf design. The PX-1000 optimizes use of the reactive ions found in RF plasma, increasing treatment uniformity while decreasing process time.

• Dimensions Chamber: 457W x 610D x 457H mm (18W x 24D x 18H in),

• Volume 127 liters (7776 in³)

• Variable Electrode Configurations Direct, Downstream

• Number of Shelf Positions 14 (we recommend 7), Shelf Pitch 25.4mm (1 in) for 600W

• 2 Mass Flow Controllers (sccm flow rates can be modified to Customer’s spec)

• Baratron gauge for pressure monitoring

• Vacuum valve

• SEMI S2-S8 Compliant, CE Compliant

• Power: 200-240 VAC, 3 phase, 25A

• Purge Gas: 0.25 inch Swagelok compression fitting for 50-80 psi Nitrogen or clean dry air (CDA)

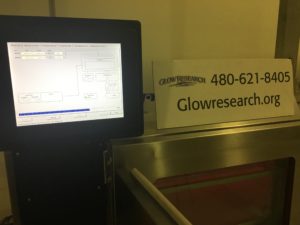

New Glow Research Genesis touch screen software control for PX-1000 system

• Touchscreen / Touchscreen control

• System pre-process self-check (MFC’s, baratron, pressure, etc.)

• Multiple step recipes—easy to configure

• Adjustable gas stabilization times, confirm MFC linearity

• Data logging, store/download historical records

• Monitor RF on/off times, during process, pressure curves during process, pressure curves during process

- We can supply multiple systems

- We can upgrade your March PX-1000, PX-500 or PX-250 system

- We supply RF Generators and Matching Networks as well

March PX-1000 nitrogen plasma in chamber

March PX-1000 Plasma System with Glow Research Genesis Software Control

March PX-1000 Stainless Steel Chamber

click HERE to see a video on the software for this PX-1000 system

click HERE for information on March PX-250 systems

click HERE for information on March PM-500 systems