Plasma Etching of Silicon Nitride (Si3N4) for RIE Removal for Failure Analysis

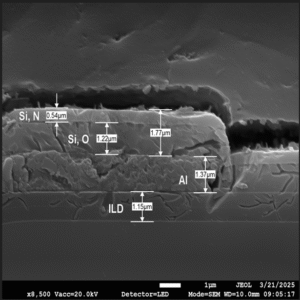

The goal was to remove the nitride layer on delidded semiconductor parts for oxide coverage inspection. Further goal was not to etch down to the metal layer. Below is the SEM shot showing the stack-up of the part with various device layers:

Layer Stack of the device

Thickness of layers:

Si, N: 0.54µm

Si, O: 1.22µm

Al: 1.37µm

ILD: 1.15µm

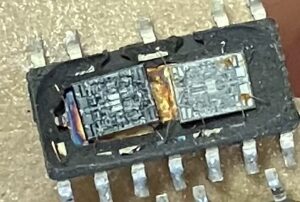

one of the samples that were etched

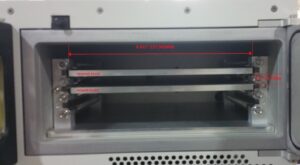

The AutoGlow 200 plasma/RIE system was used to perform this task with the following conditions:

- AutoGlow 200 in the RIE mode (with sample resting on the bottom power plate with the ground plate above).

- Pressure 550 mTorr

- 90% SF6

- 10% O2

- 100 watts

- 5 min

AutoGlow 200 chamber in RIE mode

Picture below: We ran a piece of a nitride on a broken silicon wafer to confirm the nitride etch. See attached picture showing yellowish looking nitride wafer piece (before), and after etch picture showing removal of the nitride (looks clear or white). Showed success with plasma Etching of silicon nitride (Si3N4) with RIE removal for failure analysis.

Test to confirm removal of nitride

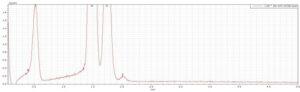

EDS graph showing oxygen, aluminum and silicon. Note: no nitrogen peak

Graph above: After etching the samples, we had a local lab in Phoenix, AZ — Semtech Laboratories inspect the samples for nitrogen with EDS. https://semteclaboratories.com/about

Analysis confirms that the Si3N4 was removed.

Semtech reports: 250s count at about 2kcps. Could not find nitrogen, which shows removal of the Si3N4 (according to our Customer). Spectrum attached (see above). The first peak at about 0.5kev, is oxygen, second peak is aluminum, and the third peak is silicon. 250 seconds and 1000 counts per second.

The AutoGlow 200 is a very economical plasma/RIE system that can be used for removing nitride and oxide layers for FA and other applications.

We have a Customer in Europe, Texplained, that uses the AutoGlow 200 for removing films for Failure Analysis. Oliver Thomas, president of Texplained, recently presented at Hardwear.io USA 2025: Making IC Supply Chain Validation Easier For Open-Source Silicon Here is a video of the presentation by Oliver Thomas: https://www.youtube.com/watch?v=srbeubi005U

Should you want to contact Texplained, their web site is: https://texplained.com/

Click here for more information on the AutoGlow 200/300 used for FA: https://www.glowresearch.org/autoglow-plasma-system/

Click here for more information on FA plasma etching: https://www.glowresearch.org/plasma-applications/plasma-etching-passivation-nitride-and-oxide-failure-analysis/

AutoGlow 200/300 can process up to 8″ wafers