Inductively Coupled Plasma (ICP) with RF Matching Network

Inductively Coupled Plasma (ICP) with RF Matching Network can be used with Glow Research plasma systems or provided as a module source for various plasma systems. The Glow Research Inductively Coupled Plasma, ICP Source/System have been tested to a base pressure in the 10-7 Range, and are designed to operate in the 5-15 mTorr range. Inductively Coupled Plasma

- Custom designed to interface with various plasma systems

- Production proven RF matching network is one of the keys to our success with this ICP source

Advantages and Benefits of ICP source with our Matching Network:

– Excellent strip rates and uniformity (photo resist strip and descum) characteristics have been achieved

– Low generation of damaging species such as charged particles, UV radiation and less heat production by the plasma.

– More efficient in producing neutral reactive (atomic and molecular) oxygen species active in the plasma process.

– Very low percentage of the power goes into the production of charged particles and UV radiation.

– Very low levels of wafer charge damage and contamination by both heavy metals and mobile ions.

– Produces a high pressure/low energy plasma

– More efficient in producing neutral oxygen atoms and reactive species by dissociation of oxygen molecules

Further points:

– High frequency (RF) electric current is passed through a helical coil which circles a dielectric-walled chamber to couple power into the electrons in the chamber.

– A multi-turn coil surrounds the cylindrical chamber, and the RF current in the coil creates a predominantly axial magnetic field within the chamber.

– The induction electric field sustains the plasma discharge as it drives electrons in a circumferential direction around the axis of the cylinder.

– Because the electric field has the same sinusoidal time dependence as the current in the coil, the electrons are driven alternately clockwise and counterclockwise at 13.56 MHz.

– Low heat and ion flux to the walls mean lower etch rates of the plasma chamber walls, thus permitting use of fluorinated chemistries (ceramic chamber is recommended for use with fluorinated process gas).

– Produces no wafer charge damage and very low contamination by heavy metals and mobile metals such as sodium.

– Superior efficiency in producing the neutral reactive oxygen species active in the strip or descum process.

– Lower production rate of damaging species such as charged particles and UV radiation, thus permitting less heavily baffled gas flow.

– Lower rate of wall erosion by sputtering or etching compared to microwave plasma sources.

– The ICP source provides advanced process capabilities with minimal impact on the plasma vessel lifetime

ICP work performed for Customer – July of 2022

-Peak power was 2KW

-13.56 Mhz

-Pressure was run from 2T to below 60 mT (pump was the limitation on the lower pressure, match was the limit on the high pressure)

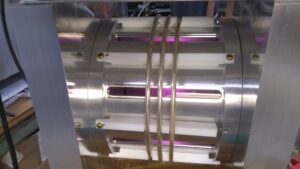

-ICP pictured has been tested with argon and oxygen (see below)

-For low pressure ignition we used a high voltage supply

-ICP was controlled by the Genesis software controller (click HERE for video and details on the Genesis software control–same control software as the AutoGlow 1000)

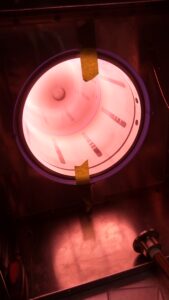

ICP with argon process gas

ICP Source

ICP during test

The Glow Research Inductively Coupled Plasma source and tuning network are offered as a complete module. Glow Research works with various plasma equipment companies and semiconductor companies to provide this ICP/tuning network for various systems and applications. Please contact Glow Research for more details and discussions. Click HERE to contact Glow Research International.

Click HERE for more information from Wikipedia on ICP sources.