AG 200 etch diagram 6-20-23Plasma etching passivation nitride and oxide for Failure Analysis (FA) in a Glow Research AutoGlow 200 plasma system.

“Autoglow 200 is simple yet powerful, and makes it easy to remove silicon nitride passivation from semiconductor devices.”

Volodymyr Pikhur”

Hardware Root Research LLC

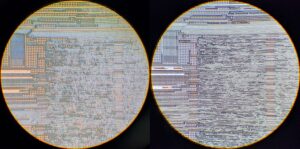

Here are some before plasma nitride etch (left) and after plasma nitride etch (right) pictures of the 8″ wafer:

Before and after nitride etching removal

SF6 gas can be used for removing oxide layers or nitride layers. Our results on the AutoGlow show the following etch rates for various films:

- Etching nitride: 800 mTorr, 200 watts, 2 min.,150mm wafer = 212 Angstroms/min Power can be increased to increase etch rate

- Etching oxide: 800 mTorr, 400 watts, 10 min, 150mm wafer = 800 Angstroms /min Power can be increased to increase etch rate

- Etching silicon: One Customer reports etch rate for silicon of: 1 um/min at 300W and 600 mT.

- Removing photoresist: 750 mTorr, 300 watts, 10 min, 2″ x 2″ substrate = 1000 Angstroms/min

The AutoGlow 200 is a cost effective way to perform Plasma etching passivation nitride and oxide for Failure Analysis (FA)

AutoGlow 300 System with End Point Detector

Recent testing in the AutoGlow 200 for a Customer using the AutoGlow 200 for FA

Using The Glow Research AutoGlow 200 for removing Nitride, Oxide layers on patterned wafers, and parts of wafers. Polyimide was removed as well.

Nitride and Oxide Process:

Preheat chamber for 15 minutes using CF4/O2 @ 200 Watts, 0.800 Torr.

Run each set of samples separately—vary the time from 1-10 min.

Gas used for nitride and oxide: 90% CF4, 10% O2

Gas used for polyimide: O2

Power: 200 watts

Pressure: .8 Torr

Nitride + Oxide patterned

Polyimide (blanket layer)

Configuration:

AutoGlow 200

2 Gas configuration

300W, 13.56 Mhz generator

Electrodes in RIE configuration (see diagram below)

Summary

Each category of samples (Nitride + Oxide patterned, and Polyimide) were processed in the AutoGlow 200 system. The time of process was varied for each category to be able to show the degree of etch. Visually, each category shows that the plasma process has removed the desired material.

The AutoGlow 200 system shows removal of oxide, nitride and polyimide.

The final process was to determine uniformity across a single 6” blanket oxide wafer. This wafer was positioned, centered, on the powered electrode (RIE mode). Uniformity shows 10.9%. Uniformity measurements defined and calculated using: Maximum measurement – Minimum measurement / 2x the Average

| Test Point | Measurement before process | Measurement after process | Etch removal in Angstroms |

| 1 | 10200 | 2964 | 7236 |

| 2 | 10230 | 3345 | 6885 |

| 3 | 10260 | 2611 | 7649 |

| 4 | 10133 | 3984 | 6149 |

| 5 | 10158 | 3811 | 6347 |

Average Etch Rate = 6853.2

Uniformity = 10.9%

For more AutoGlow 200/300 information and a video click HERE

For a partial list of Glow Research Customers click HERE.

Other papers that discuss plasma etching of passivation nitride and oxide–click HERE