300mm Plasma Descum System was tested at the Glow Research Lab. Photoresist removal testing showed uniformity of less than 9% using one electrode shelf set (powered bottom shelf, grounded electrode shelf above). An photoresist removal rate of 148 Angstroms/min was achieved on the 300mm plasma etch of oxide. The AutoGlow 1000 can be used for processing multiple 300mm wafers on multiple shelves. The AutoGlow 1000 channels the process gas to the front of the chamber in a balanced way to improve the uniformity on large substrates. Process gas is introduced to the front of the vacuum chamber and the reactive gas plasma is drawn across the substrate(s) to the vacuum port in the rear of the chamber. The plasma is extremely uniform. Other films such as photoresist, polymers, silicon nitride and organics can also be processed in the AutoGlow 1000.

Testing performed for the 300mm Plasma Descum System:

- oxygen as the process gas

- 1 Torr pressure

- 200 watts of power at 13.56 MHz

- 10 minutes

- 148 Angstroms/min is the etch rate

- 300mm Plasma descum of photoresist electrode configuration: resting on the lower powered electrode with ground electrode positioned above the powered electrode (RIE mode)

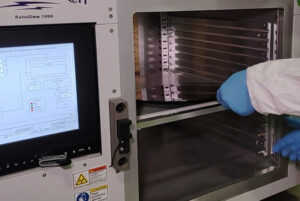

The AutoGlow 1000 can process multiple 300mm wafers on multiple electrode shelves

AutoGlow 1000–showing two sets of electrode shelves

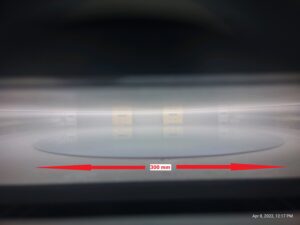

300mm Silicon Wafer in the AutoGlow 1000 Plasma System. Note active oxygen plasma.

300mm wafer, PR in the AutoGlow 1000

Glow Research makes the entire system–the RF generator, Matching Network, Software control system, chamber, gas delivery system and the electrode shelves. Electrode shelf sets can be ordered. Also offered is a perforated ground shelf–where the substrates would rest on the bottom floating ground under the perforated connected ground shelf. This provides a “down-stream” plasma discharge for applications where the user is concerned with ion damage to the substrate.

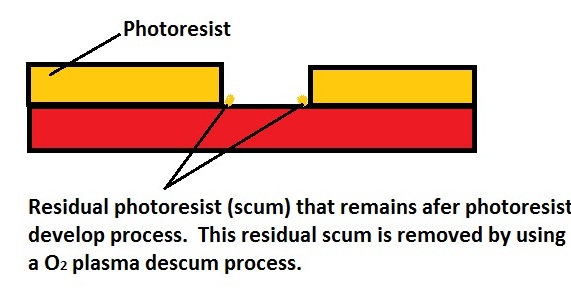

300mm Plasma Descum System: This procedure is used to remove thin residual layers of photoresist areas following photoresist development. These residual films are typically less than 1,000 Angstroms thick, but can interfere significantly in resolving the pattern during etching, especially if the pattern geometries are small (such as contact windows).

- For more AutoGlow 1000 information and a video, click HERE

- For descum information on our AutoGlow 200/300 click HERE

- Click HERE to link to a paper on plasma descum and doping from ECS/Micron Technology. The descum process is temperature-sensitive process. It has been demonstrated that the process is very sensitive to silicon substrate doping, which impacts wafer heating.

- If you have interest or would like to run samples, please click HERE