- Plasma Cleaning Titanium Alloy Surfaces.

- Here is a research paper by our Customers at Orthobond Inc: Jordan Katz, Sophia Gershman & Abraham Belkind. Click here to view this good work.

- The Glow Research AutoGlow plasma system was used for some of this work.

- Orthobond Inc., North Brunswick, NJ 08902; 2A. Belkind & Associates, LLC, North Plainfield, NJ 07060

- Address all correspondence to: Jordan Katz, Orthobond Inc., 671 US Hwy 1, North Brunswick, NJ 08902; Tel.: 732 729 6235; Fax: 973 476 9085; katzj@orthobond.com

Plasma Cleaning Titanium Alloy Surfaces using Optical Emission Spectroscopy and Contact Angle Study. Using Argon Plasma Cleaner.

ABSTRACT:

Plasma cleaning is common in the preparation of titanium medical devices. In this study, we examine the use of continuous in situ measurements with optical emission spectroscopy (OES) during plasma cleaning and wet contact angle as a tool to assess titanium implant cleanliness.

Plasma Cleaning Titanium Alloy Surfaces was performed in argon plasma at 66.7 Pa in a commercially available radio-frequency (RF) power plasma system using 25 or 100 W of power. During cleaning, the intensities of OES lines at 386 and 418 nm, as related to surface contaminants, decreased over time and reached a baseline level in ~1 h. However, the water contact angle (WCA) decreased more rapidly, reaching ≤10 degrees in 3–5 sec and further decreased to the limit of detection of ~1 ± 1 degree in 20 min using 25 W plasma and in 1 min using 100 W plasma.

The OES data indicate that plasma cleaning starts with rapid removal of contaminants from pronounced regions that are better exposed to the plasma and is followed by prolonged cleaning related to the removal of contaminants from less accessible regions. The delayed rise in WCA demonstrates a limitation in using that technique to assess cleanliness and shows how OES is a useful tool to better understand and control plasma cleaning of titanium surfaces.

Find the paper here

- Here are some results and graphs:

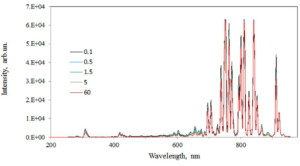

Optical emission spectra of 100 W Ar plasma while cleaning untreated CP Ti

foil. Spectra recorded during cleaning at various indicated plasma exposure times (min).

Optical emission spectra of 100 W Ar plasma while cleaning coupons of untreated

CP Ti foil, coated with Ti + PUL (PAL) and Ti + TPL (TPL). Spectra were recorded

during cleaning at various indicated plasma exposure times (min).

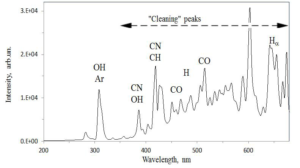

Optical emission spectra of Ar 100 W plasma while cleaning coupons of untreated

CP Ti foil. Spectra were recorded during cleaning after 5 s of plasma exposure time. Probable emission peak identifications are shown in the graph.

SUMMARY AND CONCLUSION

Plasma Cleaning Titanium Alloy Surfaces is an important step in the preparation of parts for various

applications in medicine. XPS and Auger spectroscopy have been used to characterize

the cleanliness of Ti surfaces, but those techniques are expensive, require high-vacuum

systems, and are not applicable for routine control of metal-surface preparation.

We show that OES can be used during plasma cleaning to track the disappearance of spectral lines related to surface contaminants on CP Ti. We have identified cleaning reference peaks at 386 and 418 nm that correspond to known surface contaminants and are reduced as a function of plasma power and cleaning time. We also demonstrate that this technique provides information beyond the “limit of detection” of contact angle, which is commonly used for assessing the endpoint cleaning of Ti surfaces. The recovery of contact angle from a WCA of 0 is delayed in samples that were cleaned with longer

durations of Ar plasma, thus demonstrating that a contact angle of 0 is not an appropriate measurement to ensure that a Ti part is completely cleaned. In medical applications where robust cleaning is essential for success, OES may be an appropriate tool.

For more information or a video of the AutoGlow plasma system click HERE

Plasma Cleaner used for Cleaning Titanium Alloy Surfaces