Production plasma system. The AutoGlow 1000 plasma system is a production plasma system with advanced software control.

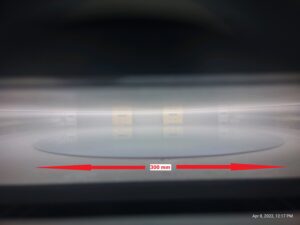

Production plasma system can be used for 300 mm wafers – AutoGlow 1000 is used for surface modification, photoresist removal, plasma descum, treatment prior to bonding, oxide etch, nitride etch, polymer etch and general plasma cleaning. The chamber is made of thick aluminum and reinforced on all sides to prevent internal bowing. The RF generator, MFC’s, baratron and all internal electronics are easy to reach for serviceability. The chamber has multiple removable and adjustable shelves to accommodate various types of carrier, samples including magazines, wafers or trays. Photoresist removal test show less than 8% uniformity using three shelf pairs. Multiple electrode shelves can be arranged for various plasma conditions: Reactive Ion Etch, Production plasma system processing and downstream plasma processing. The AutoGlow 1000 can process 300mm wafers.

AutoGlow production plasma system used for etching, cleaning and surface activation

- 30 to 600 watts (13.56 MHz) 30 watts for gentle processing—high power for more aggressive applications. Optional 1000 watt RF generator available.

- 13.56 MHz (high frequency) with auto-tune. Optional 100 kHz available.

- Can set power in one watt increments—the RF generator and match network are tuned to accomplish this

- Glow Research makes the entire system (RF generator, RF tuning network, software control system, chamber and gas delivery system)

- Automatic Tuning—very fast and with extremely low reflected power—very well designed tuning network

- Throttle valve for controlling chamber pressure independent from gas flow

- Genesis Software with diagnostics, lock outs, and advance control

- Choice of up to four Mass Flow Controllers

- Designed for ease of service—RF generator and the electronics/gas distribution modules slide out the front

- CE marked and certified. NRTL certifications upon request.

Exterior Dimensions

• 32″ Wide (81 cm) x 24″ High (61 cm) x 43″ Deep (89 cm)

Chamber Material

• Aluminum

Chamber Interior Dimensions

• 18″ Wide (46 cm) x 18″ High (46 cm) x 24″ Deep (61 cm)

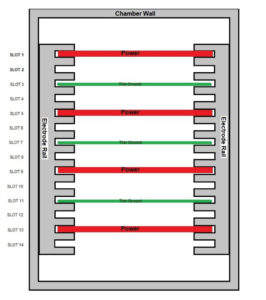

Number of Work Shelves

(see diagram)

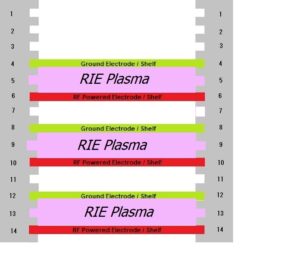

AutoGlow 1000 chamber with 7 electrode shelves

Work Shelves Surface Area

• Power Shelf 13.75″ (35cm) Wide x 16.75″ (42.8cm) Deep

• Ground Shelf 16″ (40.9cm) Wide x 17.5″ (44.8cm) Deep

AutoGlow 1000 showing RIE shelf configuration

RADIO FREQUENCY POWER GENERATOR AND MATCHING NETWORK

The AG1000 system is equipped with a solid state RF (Radio Frequency) generator with a fixed frequency of 13.56 MHz. Impedance matching is achieved through the employment of an intelligent Inductive-Capacitive tuning network. The tuning network functions by automatically adjusting the forward to reflected power ratio during processing in order to achieve the best power transfer to the plasma. The forward power is the actual power going into the chamber to create the plasma. Reflected power is undesirable in that it is lost from the plasma and reflected back into the generator.

300mm Silicon Wafer in the AutoGlow 1000 Plasma System with oxygen plasma (from the viewport window)

For a video on the software control system click HERE

For details on oxide etching in the AutoGlow 1000 click HERE

For details on plasma descum in the AutoGlow 1000 click HERE

For information on plasma treatment for epoxy bonding click HERE